Spore trap analysis [ST]

Published: July 8th, 2009

Revised: March 24th, 2023

Spore trap sampling involves collecting airborne particles on a filter membrane or adhesive-coated slide by drawing air through or over the collection medium, respectively. The collection medium is then analyzed by transmitted light microscopy, usually at 600–1000× magnification. A number of different collection devices may be used for spore trap sampling of which the most common are 1) slit impactors such as the Allergenco-D or Air-O-Cell cassette, and 2) mixed cellulose ester membrane (MCEM) filters.

The normally high minute-to-minute variability in levels of airborne spores greatly limits the utility of short-term quantitative air sampling data. This large intrinsic source of variation also minimizes the importance of counting method as a significant source of error. The most critical source of error in spore trap analysis qualitative, involving the identification of spores. Spore trap analysis is one of the most technically challenging tasks in environmental mycology, requiring considerable skill and experience on the part of the analyst, to identify spores accurately, and to differentiate them from other airborne particles. A good spore trap analyst requires years of experience not just analyzing spore trap samples but examining whole specimens from field collections in order to learn the full variation of fungal structures as well as particles that might be confused with them. This level of experience cannot be trained in a short time, and it cannot easily be acquired by individuals lacking advanced training in mycology or botany. All of our analysts have extensive, supervised experience in fungal spore identification. They participate regularly in proficiency testing programs through the American Industrial Hygiene Association, Proficiency Analytical Testing Programs (AIHA-PAT, LLC), and they have attained independent certification of their skills through proctored examinations by the Pan–American Aerobiology Certification Board. For more information on the requirements visit the PAN-AMERICAN AEROBIOLOGY CERTIFICATION BOARD >

Spore trap sampling has an advantage over culture-dependent methods by permitting the enumeration of fungal particles regardless of culturability or viability. Because of this, spore trap sampling is sometimes incorrectly referred to as a “non-viable” sampling method; however, it more appropriately should be called a “total” sampling method, since both culturable as well as non-culturable propagules are counted. The greatest limitation of spore trap sampling is its inability to allow low-level identifications of spores due to the lack of diagnostic features on many spore types. By contrast, culture-dependent methods have the advantage of access to a variety of cell types for a given fungus, as well as a living culture that could be submitted to physiological tests, allowing other distinguishing characteristics to be evaluated. As such, spores counted in spore traps can only be identified presumptively based on their size, shape and color.

Method 1. Slit impactor sampling

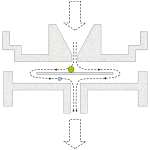

Disposible slit impactor samplers consist of a plastic housing with a tapered slit-like window on one side and an outlet tube on the other side. In the interior of the cassette, a small glass or plastic wafer is positioned slightly below the open window of the slit. The wafer is typically coated with an optically clear, sticky gel or grease. As air is drawn through the slit, particles are drawn towards the wafer. Particles of relatively small momentum will deflect with the air stream and be exhausted on the outlet side of the cassette. Particles of relatively larger momentum may be incompletely deflected at the wafer surface, and impact on its sticky surface. The size of particles captured with 50% efficiency on the wafer is referred to as the d50 cutpoint of the sampler. Particles larger than the d50 cutpoint are collected with very high efficiency, whereas particles smaller than the d50 cutpoint are poorly collected by the sampler. Most modern single-use slit samplers are individually serial-numbered and stamped with an expiry date, indicating the usable life of their adhesive and assembly.

Disposible slit impactor samplers consist of a plastic housing with a tapered slit-like window on one side and an outlet tube on the other side. In the interior of the cassette, a small glass or plastic wafer is positioned slightly below the open window of the slit. The wafer is typically coated with an optically clear, sticky gel or grease. As air is drawn through the slit, particles are drawn towards the wafer. Particles of relatively small momentum will deflect with the air stream and be exhausted on the outlet side of the cassette. Particles of relatively larger momentum may be incompletely deflected at the wafer surface, and impact on its sticky surface. The size of particles captured with 50% efficiency on the wafer is referred to as the d50 cutpoint of the sampler. Particles larger than the d50 cutpoint are collected with very high efficiency, whereas particles smaller than the d50 cutpoint are poorly collected by the sampler. Most modern single-use slit samplers are individually serial-numbered and stamped with an expiry date, indicating the usable life of their adhesive and assembly.

Field sample collection

- Calibrate a high flow air sampling pump to collect 15-20 L/min using an equivalent calibration cassette placed in-line. The selection of actual flow rate is important, since collection efficiency is lower and the particle deposit tends to become more diffuse at lower collection flow rates. While higher flow rates are generally better from the standpoint of impaction efficiency, increased air velocities tend to increase particle bounce, which may result in loss. Most manufacturers of single-use slit impactors recommend sample collection at a flow rate of 15 L/min.

- Verify that the collection medium has a current expiration date.

- Connect the vacuum hose to the outlet of the cassette. Support the cassette or hose so that the sample slit is oriented in a downward direction. Remove the slit cover.

Most manufacturers recommend sampling volumes of 150 L for generally clean indoor environments and 75 L for environments suspected to be overly dusty, or for the collection of outdoor comparison samples. Sampling volumes lower than this (e.g. 10-25 L) may be helpful in areas that are highly dusty, such as remediation enclosures or dust-generating industrial processes.

Most manufacturers recommend sampling volumes of 150 L for generally clean indoor environments and 75 L for environments suspected to be overly dusty, or for the collection of outdoor comparison samples. Sampling volumes lower than this (e.g. 10-25 L) may be helpful in areas that are highly dusty, such as remediation enclosures or dust-generating industrial processes.- At least one field blank should be collected for every 10 field samples taken. Field blanks should be handled in exactly the same manner as test samples except that air must not be drawn through them.

- Following collection, samples and blanks should be re-sealed, labeled and arranged in a clean box or bag away from moisture and light until analysis.

- Calibrate a high-volume pump with an calibration filter cassette in-line to achieve a flow rate between 2-15 L/min air.

- Connect the vacuum hose to the outlet nipple of the cassette and remove the end-cap from the front of the cassette. Samples should be collected with the cassette oriented downward in order to reduce over-sampling from gravity-related particle deposition. Ideally, between 1.0-1.2 m³ air should be collected, although lower total air volumes may be indicated in dusty atmospheres.

- One field blank handled exactly as test samples (without any air draw) should be analyzed for every 10 field samples.

- After collection, all cassettes should be sealed, labeled and placed in a clean box or bag away from light and moisture until analysis.

Method 2. Mixed cellulose ester membrane (MCEM) sampling

MCEM spore traps typically require a longer sampling period than slit-type collectors (e.g. 1–8 hr vs. 0.5–30 min, respectively). The longer-term collection however yields a more integrated, average sample, capturing transient fluxes over time. The spore catch in an MCEM sample tends also to be evenly distributed over the membrane surface, making the analysis of these samples less sensitive to sample overloading. As well, the fact that the entire spore catch lies in a single focal plane makes this sampling method appealing from a laboratory analytical standpoint.

Because fitration-based methods rely much less than slit impactors on particle momentum to capture and retain particles, filter samplers may be used over a wide range of flow rates without suffering appreciable changes in the collection yield. Typically, a 25 mm MCEM filter with 0.8 µm pore size is used for collection. Suitable filters include asbestos PCM cassettes, that are available pre-loaded in 3-piece electrically conductive cassette outfitted with a 50 mm extension cowl that reduces the dispersion of collected particles due to static electric effects. The laboratory analysis of MCEM filter samples involves the use of a “hot block” vaporizer to generate acetone vapour for clearing the filter, followed by application of a microscopic mounting fluid to the cleared surface of the membrane and examination under the compound microscope.

Because fitration-based methods rely much less than slit impactors on particle momentum to capture and retain particles, filter samplers may be used over a wide range of flow rates without suffering appreciable changes in the collection yield. Typically, a 25 mm MCEM filter with 0.8 µm pore size is used for collection. Suitable filters include asbestos PCM cassettes, that are available pre-loaded in 3-piece electrically conductive cassette outfitted with a 50 mm extension cowl that reduces the dispersion of collected particles due to static electric effects. The laboratory analysis of MCEM filter samples involves the use of a “hot block” vaporizer to generate acetone vapour for clearing the filter, followed by application of a microscopic mounting fluid to the cleared surface of the membrane and examination under the compound microscope.

Field sample collection

Laboratory code: ST

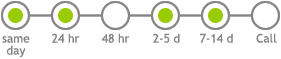

Service options

Results reporting

Results of spore trap samples will be reported quantitatively as Elements/m³ for each organism category observed. The background level of non-fungal particles is reported semiquantitatively, as 1+, 2+, 3+, etc., where the numeral preceding the plus sign indicates the level of visible background particles per optical field in accordance with ASTM D7391-09. Background levels above 3+ indicate that the quantitation of fungal particles in the sample may be unreliable due to oversampling.